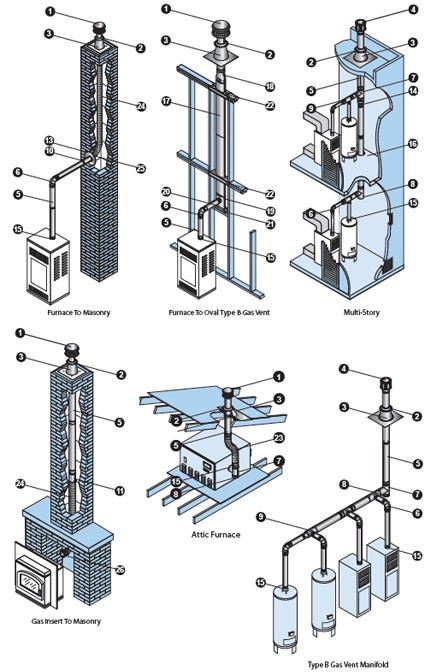

| Type B Vent Round 3″-8″ |

1 inch to combustibles |

100 feet |

5/8″ larger than ID |

Inner – .012″ Aluminum Outer – .018″ Galvanized |

DuraLock |

MH6357 |

CMH1276 |

| Round 10″ to 16″ See note 2 |

1 inch to combustibles |

100 feet |

1″ larger than ID |

Inner – .016″ Aluminum Outer – .021″ Galvanized |

TwistLock Screws |

MH6357 |

CMH1276 |

| Round 18″ to 30″ |

1 inch to combustibles |

100 feet |

2″ larger than ID See note 5 |

Inner – .020″ Aluminum Outer – .021″ Galvanized |

Screws |

MH6357 |

CMH1276 |

| Oval Type B Vent 4″ and 5″ |

2″ x 4″ & 2″ x 6″ stud wall and 1 inch to combustibles |

See Note 3 |

2 1/2″ x 7 1/4″ 3 1/8″ x 10 7/8″ |

Inner – .012″ Aluminum Outer – .018″ Galvanized |

Button Lock |

MH6357 |

CMH1276 |

| Oval Type B Vent 6″ |

2″ x 6″ stud wall and 1 inch to combustibles |

See Note 3 |

3 1/4″ x 12″ |

Inner – .012″ Aluminum Outer – .018″ Galvanized |

Button Lock |

MH6357 |

CMH1276 |

| Type B Vent 3″ to 6″ Round Liner” |

0″/Masonry |

50 feet |

5/8″ larger than ID |

Inner – .012″ Aluminum Outer – .018″ Galvanized |

DuraLock |

MH14420 MH6357 |

CMH1407 |

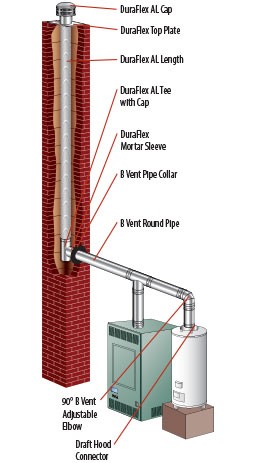

| DuraFlex AL Gas Relining 3″ to 6″ |

0″/Masonry |

50 feet |

1/4″ larger than ID |

.010″ Aluminum Flex |

Screws DuraLock |

MH14420 |

— |

| DuraConnect 3″ to 6″ |

1 inch to combustibles |

See Note 4 |

1/4″ larger than ID |

.010″ Aluminum Flex .018″ Galvalume |

DuraLock |

MH14089 |

— |

| DuraConnect II 3″ to 6″ |

1 inch to combustibles |

See Note 4 |

1/4″ larger than ID |

.010″ Aluminum Flex .018″ Galvalume |

DuraLock |

MH14089 |

— |