DuraStack®

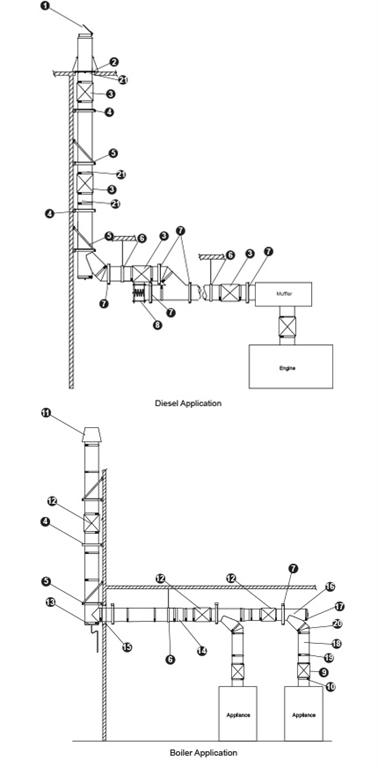

The DuraStack® Models DIS and DAS venting systems are designed to offer the ultimate in installation convenience and versatility for a variety of applications. Certified for commercial chimney as a modular double-wall positive pressure chimney system. Factory built for boiler breeching, engine exhaust, and chimney stack. Grease duct (DIS only) and diesel exhaust applications. Thick-gauge material for the inner pipe and coupling provides a strong and rigid assembly. Self-centering flue design significantly simplifies and accelerates the installation process. Coupling configuration (patent pending) requires only one locking band and the use of a regular, less expensive, high-temperature silicone sealant.

Available in sizes from 5″ to 36″ diameters, the DIS line offers double-wall, 2″ insulated chimneys, and the DAS offers a 2″ air insulated product. For premium corrosion resistance and durability, the inner wall is constructed from .035″ Stainless Steel 304 or 316. This is coupled with a .018″ Stainless Steel 304, 316 or Galvalume® (Aluminum-zinc coated) steel outer wall. The DIS is lined with the highest-quality insulation, densely packed to ensure low heat loss, maximum draft and a 1″ clearance to combustible materials.