Grease Duct

Duravent’s Prefab Grease Duct provides benefits that help owners reduce expense and risk. These benefits lower install and lifecycle costs, reduce risks and ensure less long-term headaches. They also reduce the chances for problems and conflicts between other stakeholders including contractors, AHJ’s and engineers working on your project.

PREFAB GREASE DUCT: THE SMART SOLUTION

Duravents' Factory-Built, UL-Listed Prefab Grease Duct is designed for efficiency, safety, cost savings, and compliance. It provides a plug-and-play alternative to traditional welded steel duct systems.

CUSTOMER DRIVEN FEATURES:

Installer: prefab eliminates or greatly reduces the need for hard to find, expensive welders. The product is designed to be easy to install and save time.

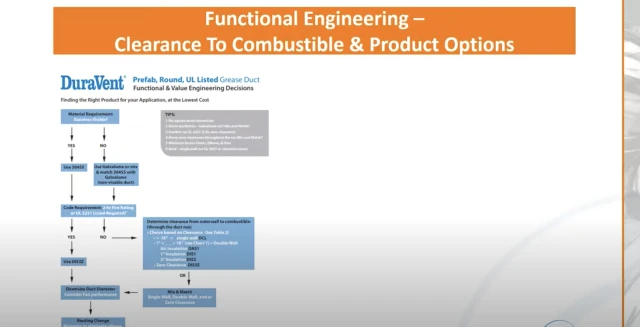

Project Engineer or Design Build Contractor: supported throughout the project by our Design Team who provide the right product for application at lowest cost.

AHJ/Inspector: benefits from easy inspections due to code compliant no-leak solutions in new or existing buildings.

General Contractor: has a project that will stay on schedule with reduced time on site for the ductwork install.

Architect: has options to save space and provide superior aesthetics due to large product line.

Owner: receives the reduced risks of a fire event occurring or the consequences if it does, as well as reduced maintenance and energy costs.

Reach out to us so we can help you reduce risks and costs while saving time on your project or investment!

Email: greaseduct@duravent.com

Why Duravent Prefab Grease Duct?

Duravent’s Prefab Grease Duct provides benefits that help Owners reduce Expense and Risk. These benefits lower install and lifecycle costs, reduce risks and ensure less long-term headaches. They also reduce the chances for problems and conflicts between other stakeholders including contractors, AHJ’s and engineers working on your project.

REDUCED RISK … LOWEST COST

Reduced Risks | Superior Warranty | Lower Costs – Install & Lifecycle Expenses

Design, Application, & Training Support

What are the Benefits?

What if you could reduce your risks of leaks during cleaning, operations and a possible fire… The Duravent prefab solution is your zero-leak option. Zero-leaks during cleaning ensures water damage during duct cleaning and subsequent mold aren’t a problem. Grease leaks during operations and fire escaping the duct are not an issue. Safety, IAQ and cleanliness are benefits of Duravent’s Zero-leak Grease Duct.

What if you could keep the job on schedule without delays and conflicts… Zero leaks and code compliant design support means your job goes smoothly, passes inspection without delays and conflicts and keeps the overall project on-schedule. Contractors, AHJ’s and Engineers have one less source of concern.

What if you could lower installation costs… a long list of Voice of Customer driven features ensures the system is installed quickly and correctly leading to lower costs, higher quality and durability.

Finding good employees will not get easier. A prefab, Plug-N-Play solution, ensures you save time on the jobsite and reduce costs using less skilled, less expensive and more available manpower.

What if you could reduce Life-cycle Expenses… stainless steel inner wall, round design, centering sleeve, no-tool tee cap and access panels are just some of the features that improve energy efficiency, quality and ease of maintenance, and durability. Additionally, there is a limited lifetime warranty

Fire-rated (DIS3Z) significantly reducing installation footprint and frees up space for other use.

No need to build an expensive fire-rated chase or apply two layers of fire wrap typically required for welded steel grease duct designs.

Certification:

UL1978, UL2221 (2 HR)

IMC, UMC and NFPA96 Code Compliance

Assembly:

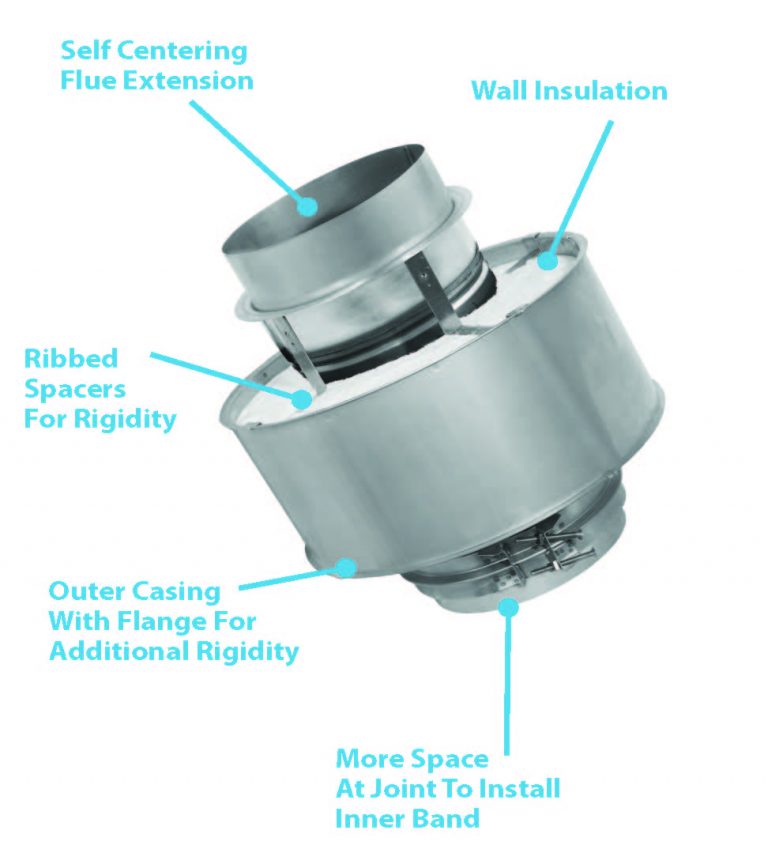

Blanket insulation is already installed in the portion that lines up with the outside casing. We provide an insulation band to be field installed behind the outside band.

Goes together with the inner flange and inner locking band (with centering extension). The outer locking band is on the outside for more support, making it a stronger system.

Diameters:

Available in 5″- 36″; 3″ wall insulation and single wall. DuraStack Pro is now UL 1978 listed for applications where 1″ air insulated, 1″, 2″, or 4″ AES Wool Insulated grease duct is required. Please see the DuraStack Pro product pages for more details.

Listings:

DuraVent, Inc. Model DIS3Z grease ducts have been tested and listed by UL to UL/ULC Standards. UL 1978 Grease Duct and UL2221(2 hr Fire Rating). IMC, UMC and NFPA96 Code Compliance.

Grease Duct is subjected to rigorous and stringent requirements of the UL1978 & UL-2221 standard, including continuous firing at 500°F (260°C), plus 30 minute firing at 2000°F (1093°C).

More Features & Benefits:

- Stainless steel construction is highly corrosion resistant and extremely durable.

- Round tubular design maintains structural integrity significantly longer than a rectangular welded steel product.

- 0″ Clearance grease duct (3″ insulation & 2 hours fire rating) eliminates the need for a separate fire-rated enclosure around the duct.

- Inner casing available in 304 or 316 stainless steel.

- Outer casing available in 304 or galvalume.

- Superior flow rate is achieved with round tube construction.

- Modular design assembles quickly with common tools.

- Contaminants of combustion are not trapped within the flue like it is commonly found in the corners of a rectangular design, thus making it much easier to clean and reduce the chance of fire from accumulated grease.

- No safety concerns with having welding on site that could cause a fire.

- Backed by a comprehensive Limited Lifetime Warranty.

- DuraStack® Pro Installation Instructions – Grease Duct (English)

- DuraStack® Pro Installation Instructions – Grease Duct (French)

Typical Installation

KITCHEN APPLICATIONS WHERE FIRE CONSEQUENCES ARE HIGH:

Where to use DuraVent Prefab Duct?

- Kitchen Proximity to Occupancy – Restaurants on First Floor below occupancy, Education, Hotels, Hospitals, Assisted Living, Childcare

- Revenue Generating/Business Disruption – Supermarket, Restaurants, Convenience Stores, Commercial/Industrial/Mission Critical Food Courts/Cafeterias

- Financial Risks – Kitchen adjacent to “other” Retail, Occupancy

- Large Projects – Stadium/Convention Center/Arena/Event Center/Casinos, Cultural/Museum, Historic Buildings & Districts, Music Clubs

How We Reduce Your Costs and Risks, And Save Time.

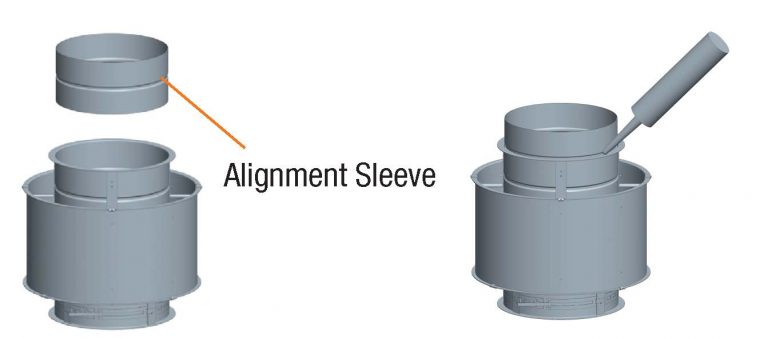

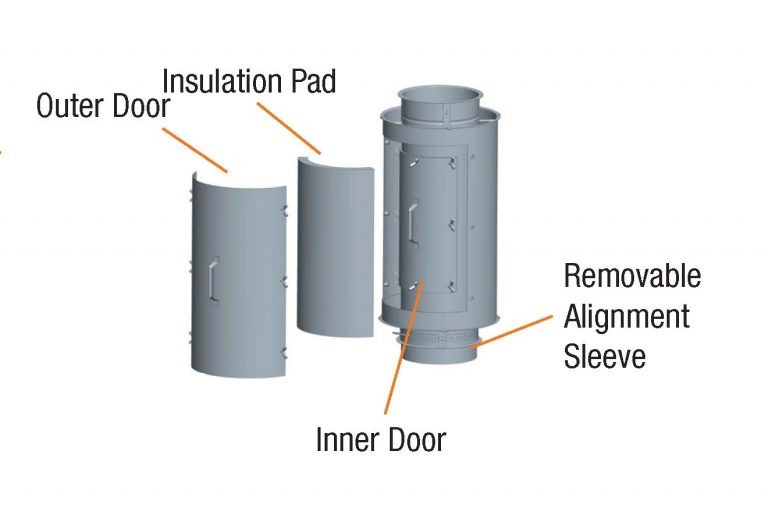

Alignment and Rigidity Sleeve Benefits:

- Installation Savings = Greater Bottom Line

- Installation Ease = Higher Quality Install

- Durability = Joint and system rigidity

We’ve improved the flanged system: Alignment or Centering Sleeve reduces installation costs and time with no leaks.

V-Band

- Captive nut and bolt.

- Eliminates loose nuts and bolts (including while on a ladder).

- Less aggravation.

More Space Between Outers

- 4 5/8” gap between outer walls vs. competitor gap of 2 1/2”.

- Protects hands by allowing more room to work which leads to improved safety and less aggravation.

Centering Sleeve: Durability

- Protects sealant from degradation and loss during cleaning.

- Especially cleaning with jet spray technology.

No-tool access tee cap

- Labor savings during maintenance. Easy, tool-less inspection.

- Doesn’t strip out after repeated usages during cleaning and inspections.

- For every cleaning and inspection, competitors’ inner bands must be taken off, old sealant must be removed from the bands, and new sealant must be applied correctly after inspection. Every time!

No-tool access door

- Labor savings during maintenance. Easy, tool-less inspection.

- Doesn’t strip out after repeated usages during cleaning and inspections.

Galvalume outer wall option

- On applications where stainless aesthetics are not required, galvalume outer wall provides significant savings.

- Galvalume can also be painted to match architectural requirements, and in corrosive environments painting provides additional protection.

- Double Wall Horizontal Offset Spec Sheet Drawing

- Double Wall Offset Spec Sheet Drawing

- Double Wall Vertical Spec Sheet Drawing

- DuraVent Grease Duct Spec Sheet

- Mixed Wall Horizontal Offset Spec Sheet Drawing

- Mixed Wall Offset Spec Sheet Drawing

- Mixed Wall Vertical Spec Sheet Drawing

- Single Wall Horizontal Offset Spec Sheet Drawing

- Single Wall Offset Spec Sheet Drawing

- Single Wall Pant Leg Spec Sheet Drawing

- Single Wall Vertical Spec Sheet Drawing

- Educational Case Study: Designing a Well-Rounded Solution for University Dining Trends

- Educational Case Study: Factory-Built Grease Duct

- Educational Case Study: How Pre-fabricated Grease Duct Keeps Restaurant Construction on Fast Track

- Educational Case Study: Made-To-Order Kitchen Exhaust A Key Ingredient In Grand Cayman Grocerant

- Educational Case Study: Restaurant Survives Grease Fire Because Factory Built Exhaust Duct Did Its Job

- Educational: What Contractors Need To Know: Kitchen Exhaust Duct

- Educational: What Owners Need To Know: Duravent Prefab Grease Duct

- Educational: What Owners Need To Know: Quick Features Comparison